2021/10/12

Inclined coil spring: introduction of inclined coil spring

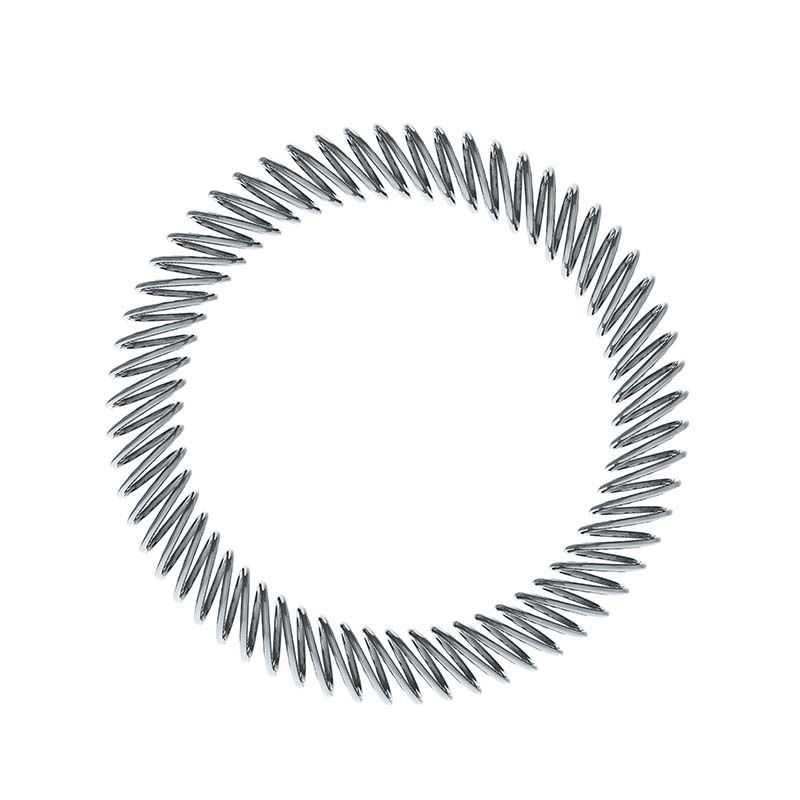

A canted coil spring is a circular spring with windings that are elliptical and sloped. When compressed, each winding will deform independently, no matter which part of the winding is deformed, the entire spring will counteract, so as to achieve the average load of each contact point. For the connector, the end of the spring will be welded to form a complete ring. For the specific insertion or extraction stress requirements of each standard coil size, in the design of the socket and plug, the spring can be placed in the groove. When the convex groove is inserted into the groove, the canted coil spring of the spring will deform under continuous spring stress and produce resistance until the coil matches the groove.

Tag:

2021/10/09

The application of spring strap contact fingers in high-voltage electrical appliances. In the power transmission and distribution industry, electrical connections must have three characteristics: safety and stability. The very small heating power, very small contact resistance and stable and uniform contact force of the spring strap can ensure good electrical connection performance. Combined with the actual design requirements and experience, the spring strap contact finger is briefly introduced.

Tag:

2021/09/28

Inclined coil spring: inclined coil spring contact finger sealing characteristics

Inclined coil spring: Mechanical seal is a safe and reliable sealing form, which is widely used in fluid sealing. In the sealing process, there is no direct contact with the rotating shaft to cause wear, so a better sealing effect can be obtained, leakage can be reduced, and the safety and reliability of the machine can be improved. The mechanical seal structure of the oblique ring spring uses the oblique ring spring as the elastic compensation element of the mechanical seal, and uses the characteristics of large elastic deformation and small elastic change of the oblique ring spring to enable the mechanical seal to obtain a better sealing effect.

Tag:

2021/09/16

Inclined coil spring: inclined coil spring contact finger sealing characteristics

Inclined spring: Mechanical seal is a safe and reliable sealing form, which is widely used in fluid sealing. In the sealing process, it does not directly contact with the rotating shaft to cause wear, so it can obtain a better sealing effect, reduce leakage, and improve the safety and reliability of the machine. The mechanical seal structure of the inclined oblique ring spring uses the inclined oblique ring spring as the elastic compensation element of the mechanical seal, and uses the characteristics of large elastic deformation and small elastic change of the inclined oblique ring spring to make the mechanical seal obtain better sealing effect.

Tag:

2021/09/12

Copper alloy springs: What is the workability of copper alloy spring strips related?

Copper alloy spring: In addition to the functional characteristics of the copper alloy spring sheet material, the processing process also plays an important role. Processability is closely related to product quality and manufacturing cost. 1. Stamping performance: The raw materials must be able to be stamped into precision parts at high frequency and low cost, which makes the materials and molds have special properties.

Tag:

2021/09/09

Copper alloy spring: What are the effects of strong pressure on copper alloy spring?

The long-term deformation of the copper alloy spring is that when the external force exceeds the elastic limit of the spring, the rebound height is lower than the original height or greater than 0.6mm. After the copper alloy spring is deformed for a long time, the elasticity and stiffness will also change. Therefore, in order to obtain a suitable spring, the spring is sometimes raised in the design drawing, and a strong compression treatment is performed after production to deform and replace the spring for a long time.

Tag:

2021/09/06

In the power transmission and distribution industry, the electrical connection must have three characteristics: safety and stability. Very small heating power, very small contact resistance and stable and uniform strap contact fingers can ensure good electrical connection performance. According to the actual design requirements and experience, the technical principles and typical applications of the contact fingers of the watchband are briefly introduced.

Tag:

2021/09/05

Copper alloys: temperatures for heat treatment of copper and copper alloys

Copper alloy: Classification of copper and copper alloy: 1. Pure copper: Pure copper is purplish red, also known as red copper. Its conductivity is second only to gold and silver, ranking third. It has good plasticity and toughness even at very low temperatures. It has a melting point of 1083, a density of 8.89-8.95 g/cm, a resistivity of 1.67-1.6810cm(20, a thermal conductivity of 391w/)MK, and a linear expansion coefficient of 17.010/. It has good stability in fresh water and seawater, the symbol t in the industrial bronze.

Tag:

2021/09/02

Copper alloy: copper and copper alloy welding some skills and types

Welding Technology of Copper and Copper Alloys 1. The thermal conductivity of copper is very high. The thermal conductivity of copper at room temperature is about 8 times higher than that of carbon steel. It is difficult for copper welding components to be locally heated to melting temperature, so energy-concentrated heat source is used during welding. 2. The welding of copper and copper alloy often cracks, the location of the cracks in the welding, welding line and heat affected zone, the crack is grain boundary damage, the section can be seen obvious oxidation color.

Tag:

2021/08/30

Copper alloy springs: Classification of copper alloy springs

Copper alloy spring we can according to the nature of its force will be divided into torsion spring, compression spring, tension spring, and according to its shape, we can be divided into copper alloy spring plate spring, ring spring, butterfly spring, torsion bar spring and so on and according to the copper alloy spring manufacturing process, we can also be divided into hot coil spring and cold coil spring.

Tag:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas