2022/04/08

Whether in industrial manufacturing or daily work life, we can see that all kinds of springs are suitable for various places. There are many types of springs. Compression springs and tension springs are two common forms of spring products. These two forms of springs have certain similarities in appearance and function, but in essence, these two springs have certain differences. Below spring contact manufacturers share what is the difference between compression spring and tension spring.

Tag:

2022/04/06

The principle of spring contact finger

The principle of spring contact finger, spring contact finger as an elastic contact, it is installed on the electrical contact between two rigid input and output. By compressing a certain proportion, an elastic force is generated, thereby ensuring reliable contact.

Tag:

2022/03/24

Alloy material: high temperature alloy material

High-temperature alloy materials, high-temperature alloy materials with excellent oxidation resistance and hot corrosion resistance in aero engines, automobile engines, gas turbines, nuclear power, petrochemical and other fields are widely used. Characteristics, the so-called high temperature alloy, that is, a kind of alloy that can work for a long time under the action of high temperature above 600 ℃ and certain stress. Compared with traditional metals, high-temperature alloy materials have high temperature and high strength in performance, good oxidation resistance and hot corrosion resistance, good fatigue resistance, fracture toughness and good elastic plasticity.

Tag:

2022/03/15

Analysis of Contact Resistance and Temperature Rise of Spring Contact Finger Structure

As a special contact, the spring contact finger is connected between the pin and the socket. Through its structural transformation, multiple contact points are generated to form electrical interconnection. Each contact point acts as a "bridge" to make the current flow evenly. Due to its simple structure, small size and low cost, it is suitable for mass manufacturing and is widely used in medium and high voltage switches, bus connectors, high current connectors, fixed electrodes, high voltage cable end pieces, fuse connectors, and mechanical and electronic applications. Below we understand the contact resistance and temperature rise analysis of the lower spring contact finger structure.

Tag:

2022/03/15

Spring touch some little knowledge

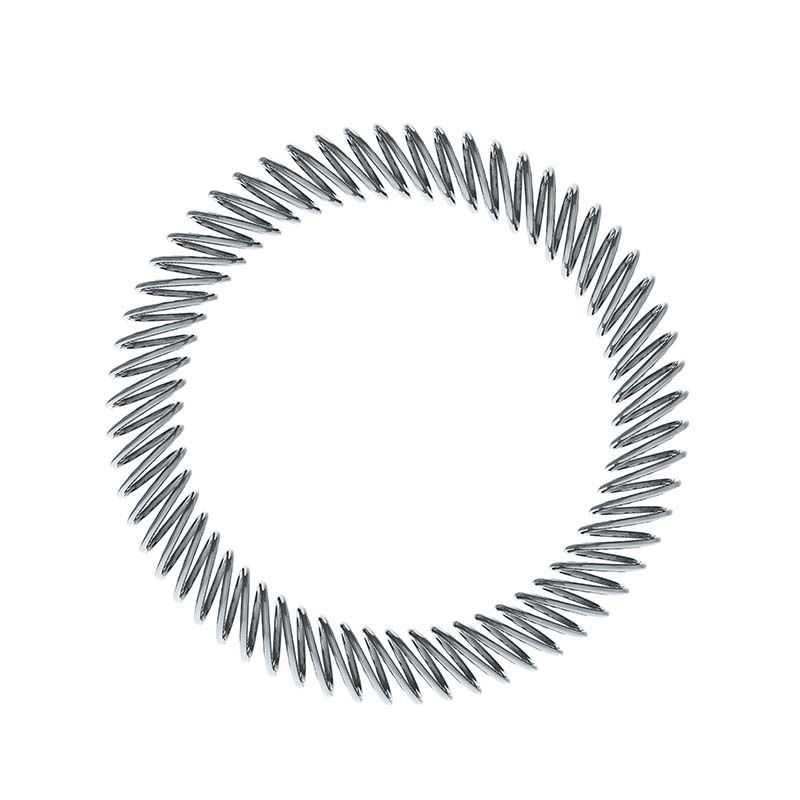

The spring contact finger is a circular coil spring whose coils are elliptical and inclined. When compressed, each coil will deform independently. No matter which part of the coil is deformed, the entire spring will be counteracted so that the load at each contact point is consistent. For the connector, the ends of the spring will be welded together to form a complete ring. For the specific stress requirements of inserting or pulling out each standard coil size, in the design of the socket and plug, the spring can be placed in the groove.

Tag:

2022/03/15

Function and advantage of spring contact finger

Spring contact finger refers to the ability to transmit strong current in a small space, and can also be used as a purely mechanical connection. There is no restriction on its use, and it is suitable for various static or dynamic medium and high pressure environments. The size of the spring contact fingers and the number of independent coil turns make the spring suitable for various electrical contact designs, and the contact points are ideal for current carrying capacity as an electrical or EMI shield. Each coil will independently compensate for contact and surface variations, which allows for greater tolerances between fittings. The multi-contact increases the conductivity, and at the same time its operating temperature is relatively low, so the service life is longer.

Tag:

2022/03/15

What are the characteristics and applications of spring finger?

As a special contact, the spring contact finger is connected between the pin and the socket. Through its structural transformation, multiple contact points are generated to form electrical interconnection. Each contact point acts as a "bridge" to make the current flow evenly. Due to its simple structure, small size and low cost, it is suitable for mass manufacturing and is widely used in medium and high voltage switches, bus connectors, high current connectors, fixed electrodes, high voltage cable end pieces, fuse connectors, and mechanical and electronic applications.

Tag:

2022/03/03

Spring touch finger you understand?

Spring contact finger: In life, spring contact finger structure is used in the fields of automobiles, electronic equipment, power connectors, etc. The head and end of this spring are welded to form a spring ring. When we encounter this kind of part structure, we often don't know it very well, and we will have questions about "what is this?" Let's take a look at the "spring contact finger" with the editor to solve the doubts and puzzles in my heart.

Tag:

2022/02/28

The spring contact finger is a circular spring with windings that are elliptical and inclined. When compressed, each winding will deform independently, no matter which part of the winding is deformed, the entire spring will counteract, so as to achieve the equal load of each contact point. For the connector, the end of the spring will be welded to form a complete ring. For the specific insertion or extraction stress requirements of each standard coil size, in the design of the socket and plug, the spring can be placed in the groove. When the convex groove is inserted into the groove, the canted coil spring of the spring will deform under continuous spring stress and produce resistance until the coil matches the groove.

Tag:

2021/10/15

Oblique coil spring: oblique coil spring touch finger

Oblique coil spring: new power electric vehicle charging pile new accessories-oblique coil spring touch finger. The rapid development of the charging pile market has also led to the development of the spring industry. Although the spring is a small accessory of the charging pile, it has a great effect. The spring of our company conforms to the change of market demand. After several years of investment and research, we finally made a charging pile tilt ring finger spring, also known as inclined coil spring finger touch.

Tag:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas